When talking to people at events, many are amazed at 3D printing and don’t know how the magic happens. It’s really not that complicated; I liken it to how, when you were a kid and you would roll your play-dough in a long snake, then wrap it around to make a basket or something else. That’s pretty much 3D printing, except, in our case, we use a plastic thread called filament. The filament is less that two millimeters in diameter and comes on a plastic or cardboard spool. The filament feeds into the nozzle which is about 220 degrees Celsius. It comes out the nozzle as a thread of melted plastic which is drawn onto a plate and the object is built layer by layer. A 3D printed house uses concrete, but it’s still the same concept of using a strand—thick or thin—of a material to build something else layer by layer.

The designers we subscribe to are artistic genius. About 95% of our toys come out as one piece, no assembly required, because the designers know how to build joints one layer at a time. These include hinge joints, ball and socket joint, and chain links. Check out a Crystal Wing Dragon, you’ll see those three joints in one piece and that is how it comes off the plate. Like I said, those people are genius.

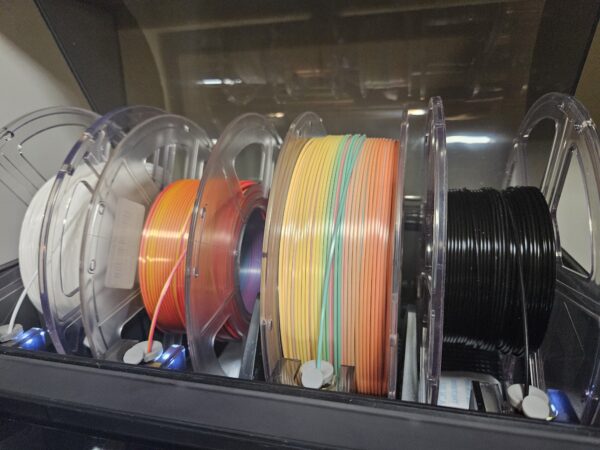

Any 3d printer can print a single filament. I hesitate to say single-color because many, if not most, of our filaments are multi color whether it be fading from one color to the next or dual/tri colors which are two separate strands of color in the one thread. If you look straight on at the end of a blue-black filament strand, you will see half the circle is blue, the other half black. To print with multiple filaments in one piece, you need an AMS. Ours hold four spools are one, but you can link up to four AMS together to create a piece with 16 different filaments. The AMS feeds the different filaments in and out of the nozzle. The print is still built layer by layer, with the machine switching filaments for each layer. Needless to say, the more filaments, the longer the print takes with switching back and forth each layer.

The bed temperature refers to how hot the plate the print in built upon is, usually about 60-65 degrees Celsius. Despite all the high temperatures, prints are ready to remove shortly after they are finished and you have a new item, ready to go.